Smitec solutions for your condition monitoring driven factory

| |||

Improved performance thanks to condition monitoring | |||

| Condition-based Monitoring (CbM) and Predictive Maintenance (PM) are two maintenance strategies which aim at optimizing equipment efficiency and reducing service timing and costs. | |||

| In a condition monitoring driven factory, the operating data of the individual machines are detected by smart sensors, sent to a central IOT platform and processed through sophisticated algorithms so as to quickly identify potential issues. Whenever a change in the health of the machine is foreseen, the condition monitoring software sends a notification so that technicians can remotely assess the situation and the actual need for a intervention on site. |  | ||

SMITEC | |||

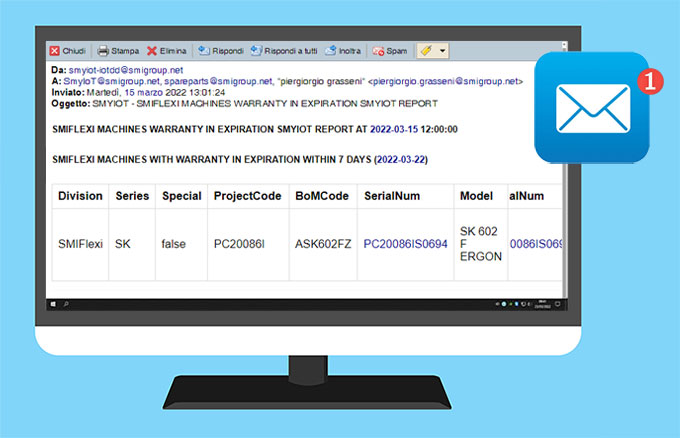

| Smitec contributes to this business intelligence model in more ways than one. The central IOT platform developed by Smitec SMYIOT monitors the operating efficiency of the machines based on specific KPIs, such as the OEE and the efficiency of the machine. It also allows to perform condition monitoring functions on the main events of the machine's life cycle, such as the approaching of the warranty expiration date or the setting of operating hours thresholds. | ||

| Specific warning notifications are generated in the event of machine warranty close to expiry date, or in case of variation from standard working or environmental conditions. An automated message system has also been implemented to e-mail notifications when interventions of scheduled maintenance are close to due date. | |||

| |||

| Predictive maintenance algorithms are being developed and close to release to keep the production plants controlled by Motornet System in perfect working order. Smitec team of engineers is also working on a set of HW solutions with the prospect of applying them to systems equipped with third parties' automation solutions. |  | ||

| For further information on the automation solutions proposed by SMITEC, do not hesitate to contact our sales department. | |||

Contact us

- SMITEC S.p.A.

- Address: Via Carlo Ceresa, 10

24015 San Giovanni Bianco BG

Italy - Phone: +39 0345 40800

- E-mail: info.smitec@smigroup.net

- Monday - Friday: 08:00 - 13:00 / 14:00 - 17:00

Saturday - Sunday: Closed

Privacy statement

TRANSPARENCY

![]()

Lawfulness of processing

All activities relating to personal data processing shall be lawful (consent, contract obligations, vital interests of the data subject or of third parties, compliance with legal obligations to which the controller is subject, public interest or exercise of official authority, legitimate interest pursued by the controller or by third parties).

![]()

Information statement

The information statement has been improved and updated to the new regulations (art. 13 and 14 GDPR).

![]()

Rights of the data subjects (right of access, right to erasure-right to be forgotten, right to restriction of processing, right to object, right to data portability)

Technical and organization measures have been adopted to ensure the data subject's exercise of his rights and to meet the data subject requirements.

![]()

Controllers, processors

Based on the new principle of “accountability”, SMI Group organization was re-defined, in order to proactively ensure integral compliance with the Regulation.

Redefinition of the role of data processors and service suppliers whose activity implies personal data processing.

![]()

Risk of data processing; accountability measures taken by controllers and processors (Impact assessment, record of processing activities, security of processing, data breach)

The “Conformity document”, including records of data processing activity, plans, adopts and demonstrates all technical and organizational measures taken to adequately perform the data processing activities and specifies the necessary procedures to be adopted to notify data breach.

![]()

Transfer of personal data to international organizations

Smitec adheres to the general principles and guarantees concerning the transfer of personal data to third Countries.

The Controller is:

SMITEC S.p.A.

Head office: Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

VAT nr: IT03790400166 - R.E.A. BG-408704

For further information, write to: privacy@smigroup.net

According to the European Regulation 679/2016, the data subject is entitled to exercise the rights set forth in the Regulation.

The integral version of art. 15; 16; 17; 18; 20; 21; 77 of the European Regulation is attached to this document.

In order to exercise your rights, please send the application form duly filled in to the Controller's address.

Legal notice

SMITEC S.p.A. con Unico Socio

Società sottoposta a direzione e coordinamento da SMIGROUP S.p.A.

Società appartenente al GRUPPO IVA SMI INDUSTRIES

Sede amministrativa:

Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

Tel. +39 0345 40.111 - Fax: +39 0345 40.209 - www.smitec.it

C.F. 03790400166 - P. IVA IT04471940165 - R.E.A. 408704

Iscr.Reg.Imprese 03790400166 - Cap. Soc. € 200.000 i.v.

Sede legale: Via Monte Grappa, 7 - 24121 Bergamo (BG) - ITALIA

Unità produttiva: Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) – ITALIA Tel. +39 0345 40.800 - Fax: +39 0345 40.809